The Leaders in GRP Catamaran Boat Building

Blyth Catamarans vessels are built entirely at our Essex based 3.7 acre site from one piece tooling for exceptional strength. All engineering work and electronics are installed by our in-house engineers. All stainless steel fittings are custom made within our own fabrication workshop, offering a complete bespoke service to our clients with a controlled quality supervision.

The company works closely with naval architects and surveyors of the highest professional standing. We take pride in our ability to construct vessels to meet or exceed the rigorous standards required for MCA Co02DE of Practice, Seafish, Irish P5 and MCA P5&6.

Maintaining the company’s position as the leading supplier of bespoke catamaran-based workboats, is one of the company’s goals. The company recognises the importance of continuous product development together with the improvement of management systems essential to support this and is proud to hold ISO 9001 accreditation.

OUR HISTORY

In 1989 Terry Searle saw a gap in the market and decided to develop the first GRP commercial catamaran workboat of its kind in the UK. The Blyth 33 was born.

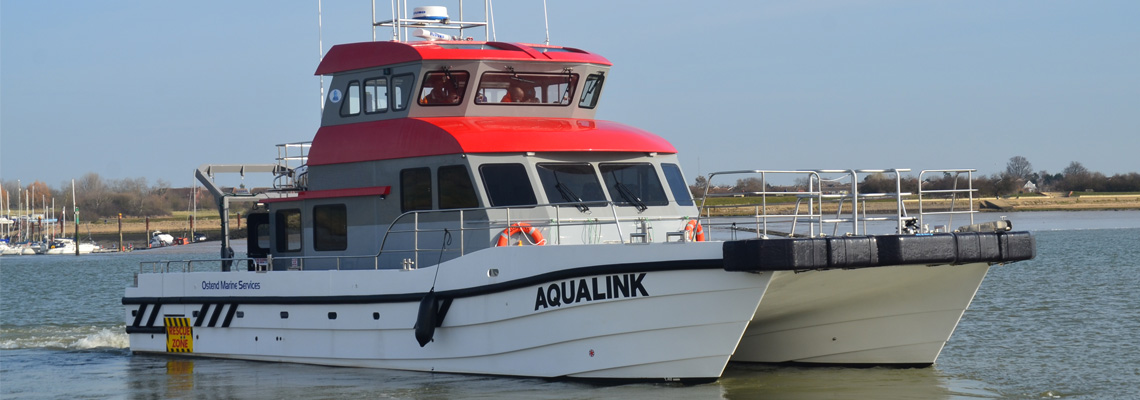

Gradually the traditional commercial workboat sector began to appreciate the benefits of the catamaran when compared to the established mono-hull; these include a significantly reduced surface area which offers the all important low fuel consumption. The catamaran workboat design also offers an exceptional working deck area which can be developed to meet a wide range of applications. The greater stability provided by the catamaran workboat was quickly identified, resulting in longer working potentials under worsening weather conditions.

There is also the ‘security’ of the second engine, not often possible with mono-hulls of 10-12m.

Years have now passed and it is testimony to both the design and construction that the original model “Jo Jo” (now renamed “Taurus”) is still operating. This workboat has been joined by over 200 Blyth Catamaran vessels in service across the world working as dive boats, anglers, potters, netters, passenger, survey, patrol and wind farm support vessels.

A Great Team Behind Our Great Workboats

The company employs a workforce who are well trained, vastly experienced and highly skilled. Blyth Catamarans is proud to have achieved accreditation to ISO 9001, ensuring every boat is built to the highest possible standards for every application intended. With our own ‘in-house’ technical department, we are able to tailor an existing, proven design to meet specific customer needs.

Blyth Catamarans

Stuart Davidsen